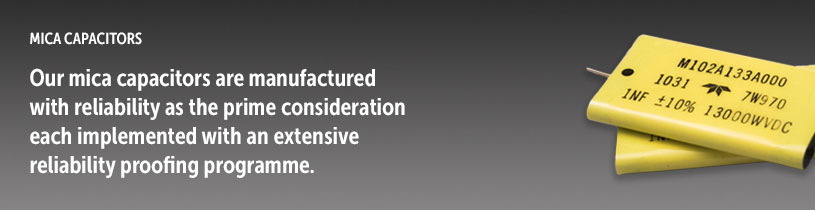

Our engineers have developed and implemented an extensive reliability proofing programme consisting of thermoset epoxy impregnated MICA dielectric systems over a period of 540,000 unit hours of operation.

Our range of Mica Capacitors include:

Available in a variety of configurations

-

Raw sections: For use in potted/embedded next higher assemblies.

-

Wrapped and end-capped: For stand-alone applications requiring no subsequent potting or embedment processes. Wrap material is Mylar® or woven glass.

-

Fibreglass encased epoxy-filled construction: Provides the attributes of the epoxy moulded configuration with no hard tooling required.

-

Low inductance/high current: Ideal for EFI (exploding foil initiators). Designed for very low inductance and high currents – available in any of the above configurations. Similar low inductance, high current designs are available for EBW (exploding bridgewire initiators).

A selection of applications

-

Epoxy moulded capacitors: Epoxy moulded assemblies can be configured in solid complex shapes and mounting arrangements. Units can contain several voltage and capacity values and a variety of terminations. These configurations offer stand-alone shock, vibration and environmental security with Teledyne Reynolds reliability. Currently qualified for use on major military and commercial programmes.

-

Mica capacitors in voltage multipliers: Raw capacitors are used in our voltage multipliers. These units have output voltages ranging to 160 kV DC. Used in a wide range of military and commercial applications. Typical applications are X-ray equipment and low power TWTs.

-

Various configurations: Epoxy moulded, fibreglass encased with epoxy filling, wrapped and end capped. Also attached to low inductance strip lines for use on EFI and EBW initiators and ESA&F systems.